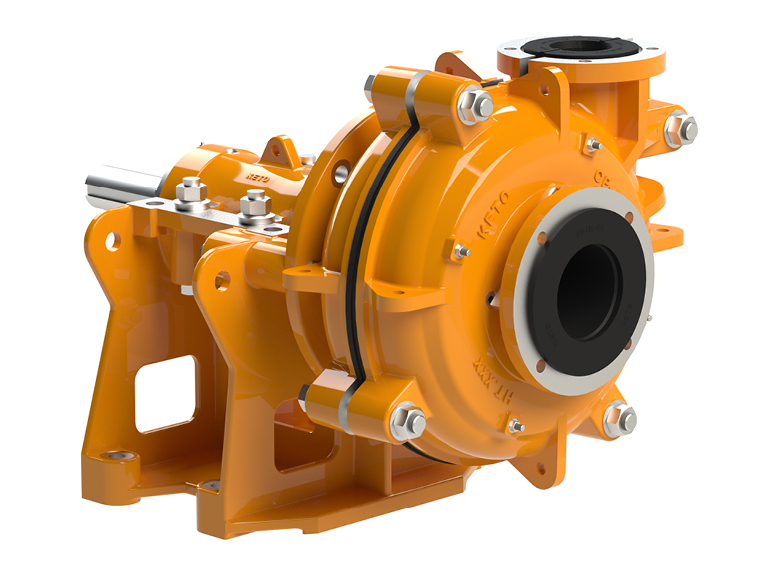

K-HSF™ Horizontal Froth Pump

Based on the K-HS™ design, but specifically designed for pumping froth. The innovative K-HSF™ Horizontal Froth pump design allows for froth and other products to be handled efficiently and without issues usually associated with pumping products with high viscosity.

An inducer blade impeller encourages positive froth feed. A widened slurry throat bush reduces NPSH required and optimises the inlet size, allowing for froth to be pumped with maximum efficiency.

An inducer blade impeller encourages positive froth feed. A widened slurry throatbush reduces NPSH required and optimises the inlet size, allowing for froth to be pumped with maximum efficiency.

SPECIFICATIONS

- Range: 50 mm (2”) to 200 mm (8”)

- Flows to: 2,000 m³/hr (8,800 USgpm)

- Heads to: 60 m (196 ft)

- Pressures to: 1,725 kPa (150 psi)

APPLICATIONS

- Froth

- Viscous slurries

FEATURES

- Wide slurry throatbush reduces NPSH required and optimises inlet size

- Interchangeable with the standard K-HS™ bearing assembly, drive end and shaft, thereby reducing site inventory levels

- Wet end uses standard K-HS™ frame plate liners and frame plates

- Inducer blade impeller encourages positive froth feed

- K-HS™ Pump can be changed into a K-HSF™ with a few small modifications

RELATED PRODUCTS

Downloads

-

Download

DownloadBrochures

KETO Company Overview Brochure